Optimized technologies have successfully helped us take our technology & product to the next level by solving our remote visibility of misjudgement across lines, and steps with smart rule engine for notification and report download feature.We would highly recommend them in terms of expertise, professionalism & value driven quality of work. Kudos to Optimized Technologies for their work.

View More TestimonialsInterface

Client Background

Meticulous craftsmanship, advanced technology, and unwavering commitment are its hallmarks. This fortress of innovation is a testament to self-reliance and serves as a sentinel safeguarding our sovereignty.

Challenges

The primary challenges faced by Ordinance Factory was a solution for collection, visualization, and analysis of the machine data that gets generated across the plant locations over an intranet based analytical platform for actionable insights and achieve the below goals:Monitoring of machine parameters.

OEE calculations for necessary actions evaluation online status for : Machine availability, Performance, Quality, Production, Scrap analysis and process optimization.

Upgrading the machines to Industry - 4.0 compliant : Sheathing Line, Insulation Line and Quadding m/c.

Solution

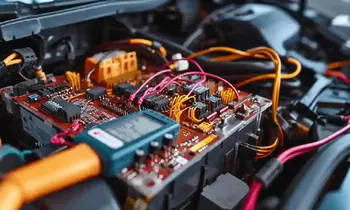

OTI developed software for real-time monitoring of sheathing lines, insulation lines, and Quading machines.The proposed solution includes the following high-level features:User management for up to ten users, with the flexibility to expand as the software is not limited by user or license constraints.Display of zone temperature, cable diameter and length, line speed, and concentricity.A dashboard for generating reports based on user-specified durations (daily, monthly, yearly, or shift-wise) for both production lines, including quantity produced (in km/m), breakdown reports, and parameter trends.An alarm feature that triggers in case of violations in OEE, breakdowns, or scrap details.This system utilizes standard components to optimize power usage, resulting in high efficiency with minimal power wastage. The components used for integration and automation are future-proof, allowing for easy expansion if the application scope increases.

Architecture

Case Study

Let us create an IoT strategy, implementation and evolve your IoT solution.

Benefits

- Monitor real-time machine parameters using industrial protocols.

- Track KPIs like OEE, machine availability, performance, quality, production, and scrap.

- Set up alerts for critical events (low OEE, breakdowns, high scrap).

- Visualize historical data with filters and generate reports (production, downtime, parameter trends).

Benefits against alternatives

- The most important benefit of our solution is its maintenance. Our solution simplified the system with the use of standard hardware components and industry standard software tech stack ensures a much better reliability and faster maintenance.

- The flexibility of the system architecture provides the client with the provision of future extensions, whether it’s the hardware or any software upgrade.