Preventive Maintenance

Preventive maintenance: Proactive strategies to identify and address potential equipment issues before they lead to costly breakdowns and downtime.

Preventive maintenance system is an approach used to ensure regular and routine inspection, correction, and repair of equipment, with the main objective being to prevent machines and other work items from breaking down.

In preventive maintenance, maintenance tasks are scheduled based on equipment usage, manufacturer recommendations, and historical data. This proactive approach allows organizations to anticipate maintenance needs, plan resources efficiently, and prevent equipment failures that can result in costly repairs and operational disruptions.

Users can program the preventative maintenance system to schedule routine maintenance jobs that are done either according to predetermined intervals, usage stats, or fixed times..

Maintenance work order software enables the generation, assignment, and tracking of planned work orders aimed at executing scheduled assignments.

With this, businesses can manage an all-inclusive log containing equipment details, services performed on it, and warranty terms, among others, for efficient monitoring of asset

The software is used to monitor and keep a count on spare part stock as well as all other associated materials and equipment needed during the repairs.

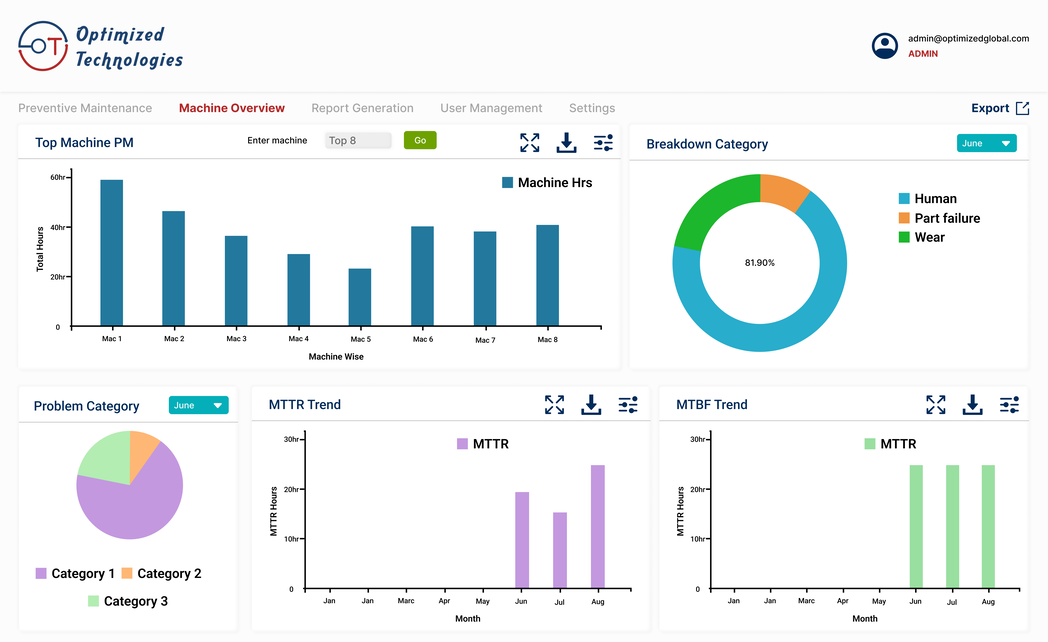

Preventive maintenance program software gives detailed reports and analytics of equipment performance, maintenance history, and costs that allow a business to create reliable data for decision-making and improve its strategies in terms of maintenance.

From a software perspective, automated alerts and notifications are sent in advance of upcoming maintenance tasks, service reminders, and critically important equipment issues, which keep the maintenance team on the edge.

Modern preventive maintenance software is able to gather real-time data through integration with IoT equipment, which makes it possible for predictive maintenance to be practiced for early prevention failure detection.

In this regard, many of today’s preventive maintenance systems allow mobile access, enabling field maintenance crews to retrieve, report, and edit current records, work orders, or scheduling directly from their devices, hence streamlining operations.

Benefit from our 19 years of IoT experience. Get the best preventive maintenance services tailored to your specific business needs.

Regular inspections and timely repairs reduce the risk of equipment failures. Our proactive approach enhances safety by preventing potential hazards and promotes compliance with industry regulations.

During our ongoing maintenance of your systems, we will always endeavor to carry out a proactive approach so that you do not have more downtime periods and achieve high operational efficiency.

Regular inspections and timely repairs reduce the risk of equipment failures. Our proactive approach enhances safety by preventing potential hazards and promotes compliance with industry regulations.

Preventive maintenance allows us to identify and address potential issues before they become major problems, minimizing unplanned downtime and costly repairs, leading to long-term cost savings.

Our preventive maintenance system provides real-time information and intelligence as well as forecasts in order for us to properly plan and schedule every production to ensure optimum results.

For proper implementation of our solutions, we undertake preventive maintenance and detect potential problems for a seamless operation cycle.

Preventive Maintenance Program Software for the automotive industry helps in the maintenance of critical machinery and equipment, which increases operational efficiency.

Our preventative maintenance system helps manufacturing companies produce better with minimal disruption and failure of machines and other manufacturing equipment.

Consumer electronics maintenance services include preventive measures that help us maintain your equipment efficiently with reduced downtime, allowing our customers to be fully satisfied.

Our software enables easy maintenance of different retail assets like store equipment and facilities in a way that ensures that disruptions are minimized and customers have good experiences.

For engineering industry preventive maintenance minimizes unplanned downtime, extends equipment lifespan, and enhances overall operational efficiency, leading to increased productivity and cost savings.

We provide preventive maintenance services to the agriculture sector to help farmers manage farming equipment and improve production yield.

Optimized Technologies Inc. is a trusted IoT and Generative AI solutions provider, delivering secure, scalable, and end-to-end services for enterprises. Our deep expertise in device connectivity, data integration, and AI application design enables organizations to unlock actionable insights and automation. We build solutions with enterprise-grade security and cloud-ready scalability, ensuring performance and compliance at every stage. From consultation to deployment and continuous optimization, we provide complete lifecycle support tailored to business needs. With a proven track record across industries, we empower businesses to achieve digital transformation, enhance efficiency, and stay competitive in the era of AI and IoT.