Interface

Client Background

The client owns an Automobile manufacturing facility. The client’s customers include Tata and Toyota among others.

Therefore, a solution is proposed where they can line-wise monitor machine models (Model name, quantity, and person performing changeover) with monthly reports.

OTI Relationship with Client

This whole task requires continuous manual monitoring at the location which makes the whole process very tedious.

Challenges

The testing centers at client’s facility perform testing on Electronic Control Units (ECUs), sometime due to various reasons, the testing centers make judgment errors.

Therefore, this whole system needs to be digitally operated to aggregate the count of these judgment errors against various categories (Line wise, Model wise, Step wise) Also, crucial protection is required for to the whole system / solution (hardware, communication and software) so that the value of the proposed solution is maintained.

Solution

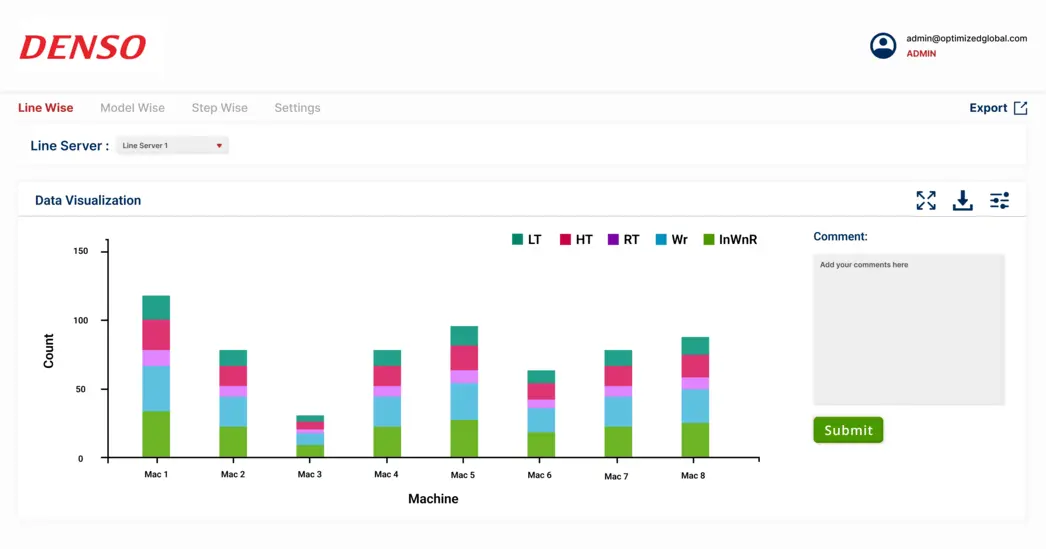

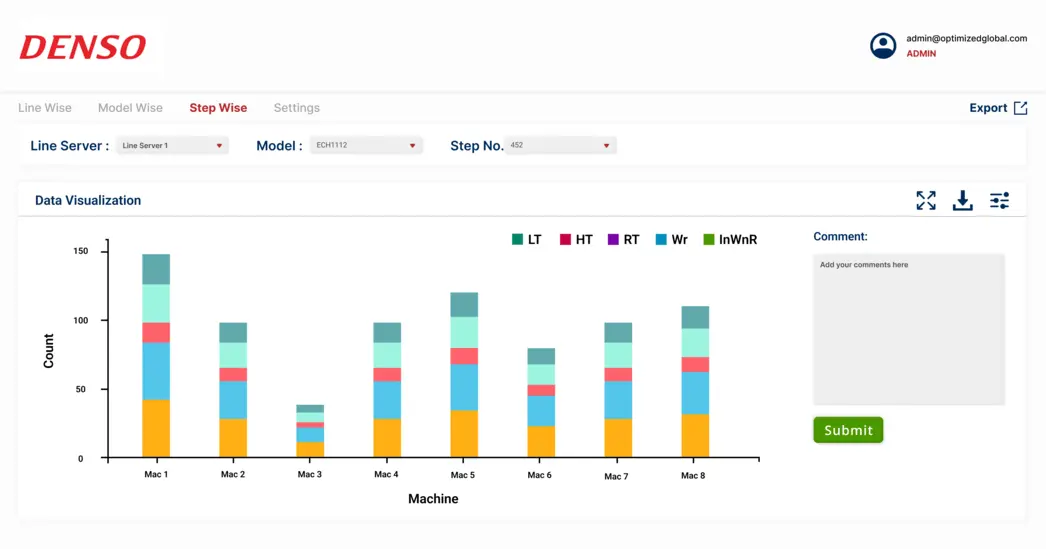

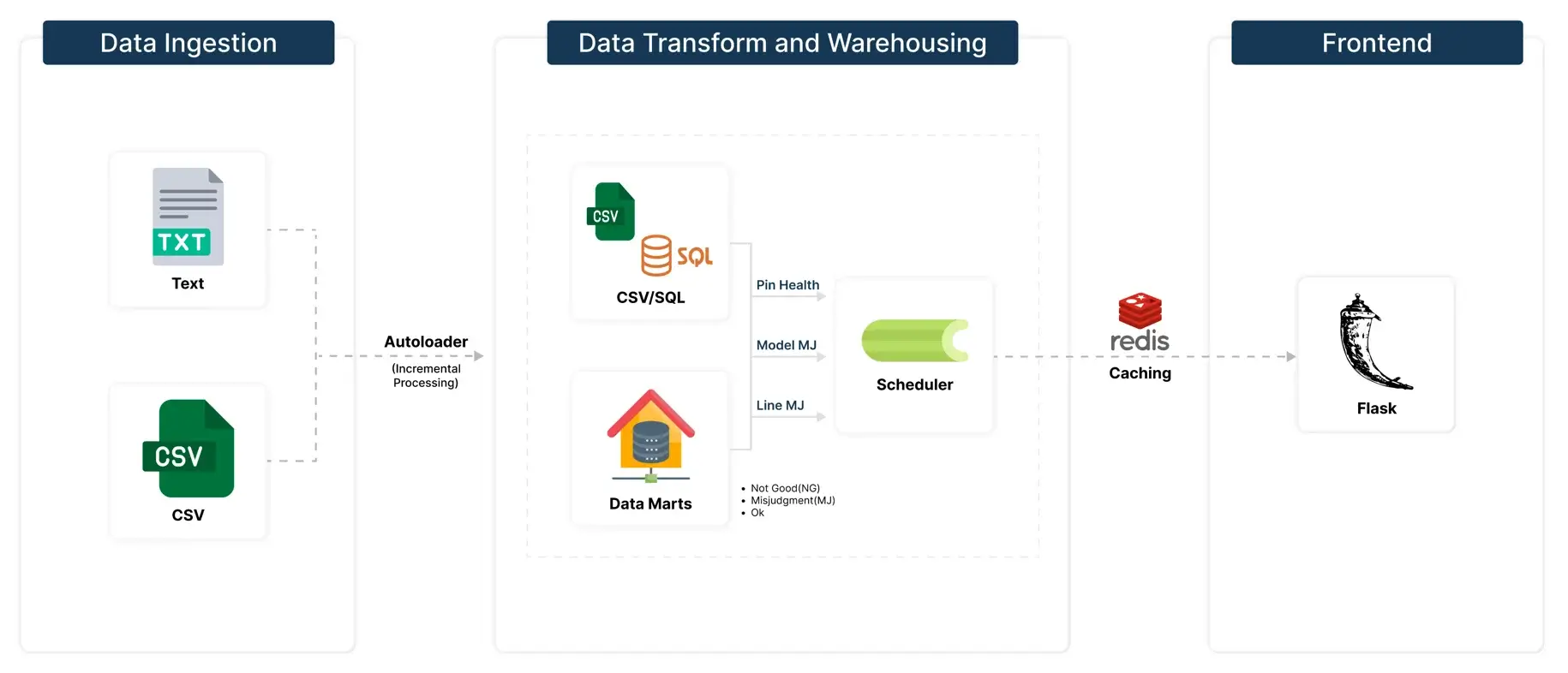

The proposed system is designed to aggregate and present misjudgment errors. The errors are categorized Line wise, Model Wise and Step Number Wise. Line here refers to machine testing line. Model refers to specific model of machine put to test. Model number is NOT mentioned in the data but has to be inferred by Serial Number. Step Number refers to kinds of tests the product is subject, examples being voltage and current. The proposed system should restrict access to authorized users only (Login Management). The application should take the path of data (CSV files) or line server from the user.

The solution should accept the label-inputs against a particular Step-Number, store it and create a downloadable table.

Generate the log reports, about status of the test (Pass/Fail). The frequency of generating log reports will be a day/shift/week.

Every time the application is executed, it has to get the summary report (Number of units tested, pass, and fail) for the designated (previous week) week of the calendar. Email Notifications of the this, every time the application is run. Internet connectivity is required.Auto run function for designated time on Sunday.

Functional Flow

Case Study

Let us create an IoT strategy, implementation and evolve your IoT solution.

Technologies We Work With

Value Proposition

Optimized Technologies Inc. has provided a system with the help of customized cloud, and Mobile application software that can handle and validate the functionalities of testing for Electronic Control Units (ECUs) on a digital dashboard.

- Data Extraction

- Data Processing

- Data Visualization

- Report Logging

- User Login Management

- Email Notification

By transforming the whole process digitally, the entire functionality of testing of ECUs has been simplified hence allowing the users to effectively monitor and analyze the whole process and overall plant efficiency.

Why Optimized Technologies Inc.?

Optimized Technologies Inc. is a trusted IoT and Generative AI solutions provider, delivering secure, scalable, and end-to-end services for enterprises. Our deep expertise in device connectivity, data integration, and AI application design enables organizations to unlock actionable insights and automation. We build solutions with enterprise-grade security and cloud-ready scalability, ensuring performance and compliance at every stage. From consultation to deployment and continuous optimization, we provide complete lifecycle support tailored to business needs. With a proven track record across industries, we empower businesses to achieve digital transformation, enhance efficiency, and stay competitive in the era of AI and IoT.