Smart Factory Solutions

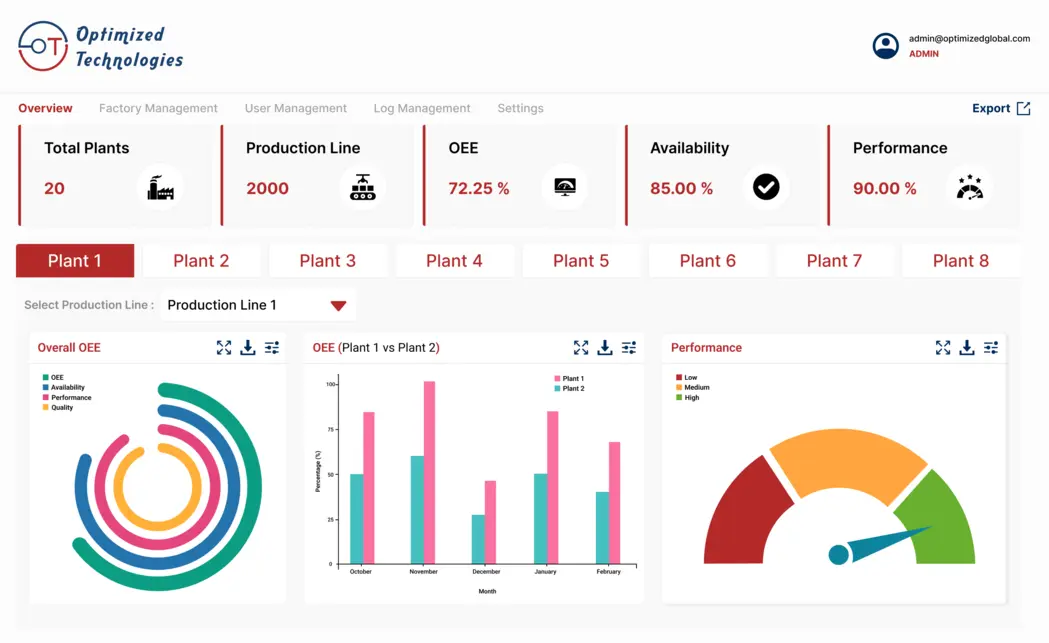

Optimize manufacturing operations, increase productivity, and enable real-time monitoring and control in the factory environment.

A digitized factory which uses an interconnected network of machines, with specific communication mechanisms, and sufficient computing power to use AI and ML to help analyse data and drive process improvements through continuous learning (as the name implies) is called a smart factory. A good example of a smart factory solution in the automotive industry is Tesla’s Gigafactory located in Berlin, Germany.

Optimize manufacturing operations, increase productivity, and enable real-time monitoring and control in the factory environment.

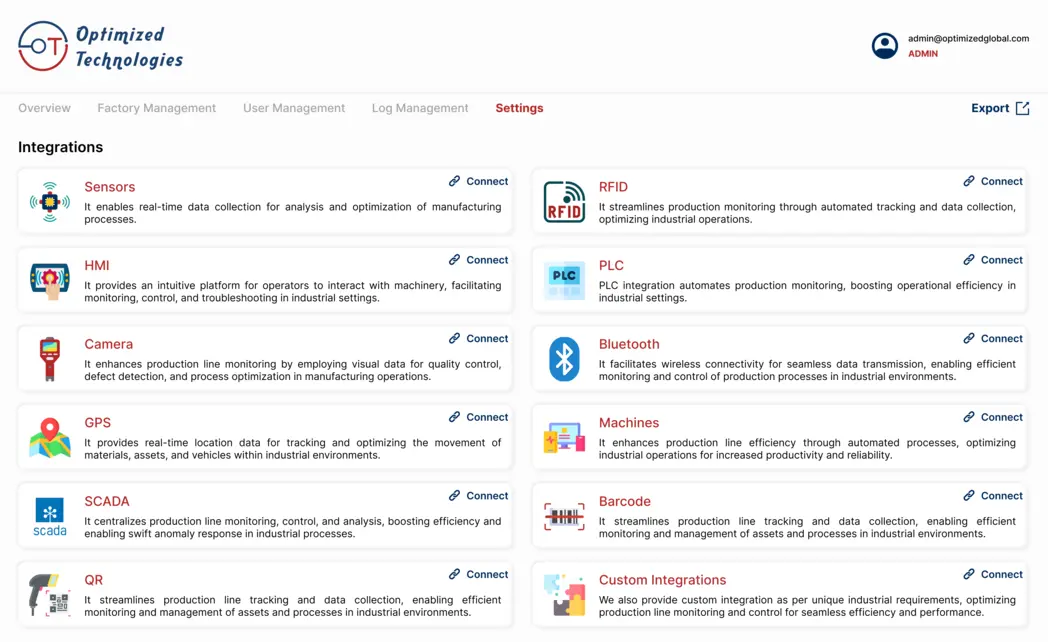

Keeping your factory requirement in mind we provide IIoT solutions involving connecting devices, machines, and systems to the internet to enable communication and data exchange. This connectivity facilitates real-time monitoring, data collection, and analysis, forming the foundation for smart manufacturing. We also setup a robust communication infrastructure, including wired and wireless networks

Sensors are deployed throughout the factory to collect real-time data from equipment, machines, and production processes. Advanced analytics and AI technologies process the vast amounts of data generated by sensors and other sources. These technologies analyze data to identify patterns, predict equipment failures, optimize production parameters, and provide insights for continuous improvement.

We build human-machine interfaces that provide a user-friendly interface for human operators to interact with and monitor the manufacturing processes. This includes touchscreens, dashboards, and other visualization tools that display real-time data and insights. Robust cybersecurity measures are also implemented at all HMIs to protect against potential threats and unauthorized access.

Depending on the nature of the requirement, we process data near the source (i.e. edge of the network, hence called edge computing) or centralized cloud servers (cloud computing). Edge computing reduces latency and allows for faster decision-making by processing critical data closer to where it is generated. Cloud computing offers scalability and accessibility, especially for advanced analytics and AI applications.

Benefit from our 19 years of IoT and Industrial IoT experience. Get the best smart factory solution to manage your Inventory.

Smart factories optimize production processes, enhance quality control, and enable predictive maintenance, leading to increased efficiency and reduced costs.

Automotive manufacturers use smart factories to streamline assembly lines, monitor equipment performance, and customize production to meet demand variations.

Electronics manufacturers leverage smart factories to enhance product quality, reduce defects, and meet rapidly changing consumer demands.

Smart factories in the pharmaceutical industry ensure stringent quality control, optimize batch processing, and enhance traceability to meet regulatory requirements and ensure product safety.

Smart factories in the food and beverage industry enhance food safety, optimize production schedules, and reduce waste through precise monitoring and control of production processes.

Manufacturers of consumer goods utilize smart factories to improve supply chain visibility, optimize inventory management, and enhance product customization to meet consumer preferences.

Optimized Technologies Inc. is a trusted IoT and Generative AI solutions provider, delivering secure, scalable, and end-to-end services for enterprises. Our deep expertise in device connectivity, data integration, and AI application design enables organizations to unlock actionable insights and automation. We build solutions with enterprise-grade security and cloud-ready scalability, ensuring performance and compliance at every stage. From consultation to deployment and continuous optimization, we provide complete lifecycle support tailored to business needs. With a proven track record across industries, we empower businesses to achieve digital transformation, enhance efficiency, and stay competitive in the era of AI and IoT.