In the era of Industry 4.0, smart manufacturing has emerged as a transformative force, revolutionizing traditional production processes through the integration of advanced technologies. At the heart of this evolution lies the Internet of Things (IoT), a network of interconnected devices that communicate and share data seamlessly. This blog post explores the significance of IoT in smart manufacturing and how it enables the realization of efficient, agile, and connected production systems.

Smart manufacturing, also known as Industry 4.0 or IIoT, is reshaping manufacturing operations. This paradigm integrates digital technologies with physical processes, creating intelligent, data-driven production environments. Real-time analytics, automation, and interconnected systems redefine efficiency and productivity, paving the way for predictive maintenance.

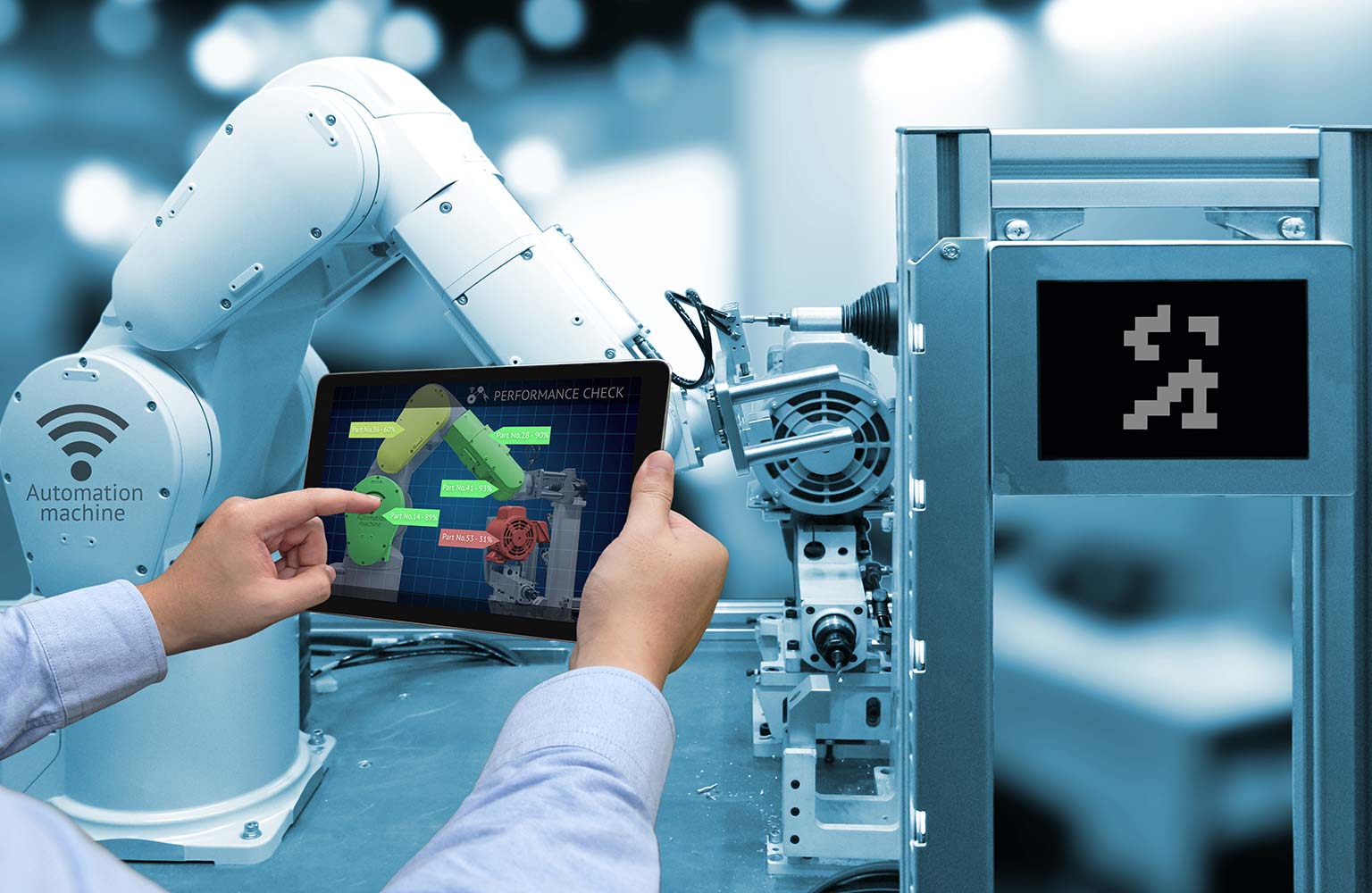

In smart manufacturing, the synergy between the digital and physical worlds is crucial. Real-time data analytics provides actionable insights for optimized processes, while automation streamlines operations through robotics and control systems.

The interconnected systems create a responsive production ecosystem, laying the groundwork for predictive maintenance and ensuring a more adaptive and agile manufacturing sector.

IoT plays a pivotal role in driving the evolution of smart manufacturing by enabling connectivity, data-driven insights, and automation across the production ecosystem. By harnessing the power of IoT technologies, manufacturers can unlock new levels of efficiency, agility, and competitiveness in today's dynamic business landscape. As smart manufacturing continues to evolve, the integration of IoT will remain a cornerstone of its success, paving the way for a more intelligent, interconnected, and sustainable future of manufacturing.

Optimized Technologies Inc. is a trusted IoT and Generative AI solutions provider, delivering secure, scalable, and end-to-end services for enterprises. Our deep expertise in device connectivity, data integration, and AI application design enables organizations to unlock actionable insights and automation. We build solutions with enterprise-grade security and cloud-ready scalability, ensuring performance and compliance at every stage. From consultation to deployment and continuous optimization, we provide complete lifecycle support tailored to business needs. With a proven track record across industries, we empower businesses to achieve digital transformation, enhance efficiency, and stay competitive in the era of AI and IoT.