Optimized Technologies embraces the manufacturing IoT boom, projecting exponential growth from USD 0.39 trillion in 2024 to USD 1.22 trillion by 2029, boasting a remarkable 25.33% CAGR. Our innovation aligns with the demand for traceability, streamlining production, reducing downtime, enhancing safety, and paving the way for the fourth industrial revolution.

North American Dominance: The primary market for IoT in manufacturing is led by North America, particularly the United States and Canada. These developed economies invest significantly in research and development, fostering the creation of new technologies.

Early Adoption and Integration: North American manufacturers have actively integrated IoT into their processes, leveraging cutting-edge technologies like mobility, big data, and IoT. This early adoption has resulted in accelerated deliveries, reduced infrastructure costs, and approximately 35% of manufacturers in the U.S. utilizing data from smart sensors to optimize manufacturing processes.

IoT Ecosystem and Growth: We drive the IoT ecosystem, integrating software, cloud computing, and analytics for actionable insights. With technological expertise and infrastructure, the region leads the global IoT market in manufacturing.

Smart monitoring systems can track the movement of materials, equipment utilization, and workforce productivity on the shop floor. This data can be used to identify bottlenecks, improve workflows, and enhance overall efficiency.

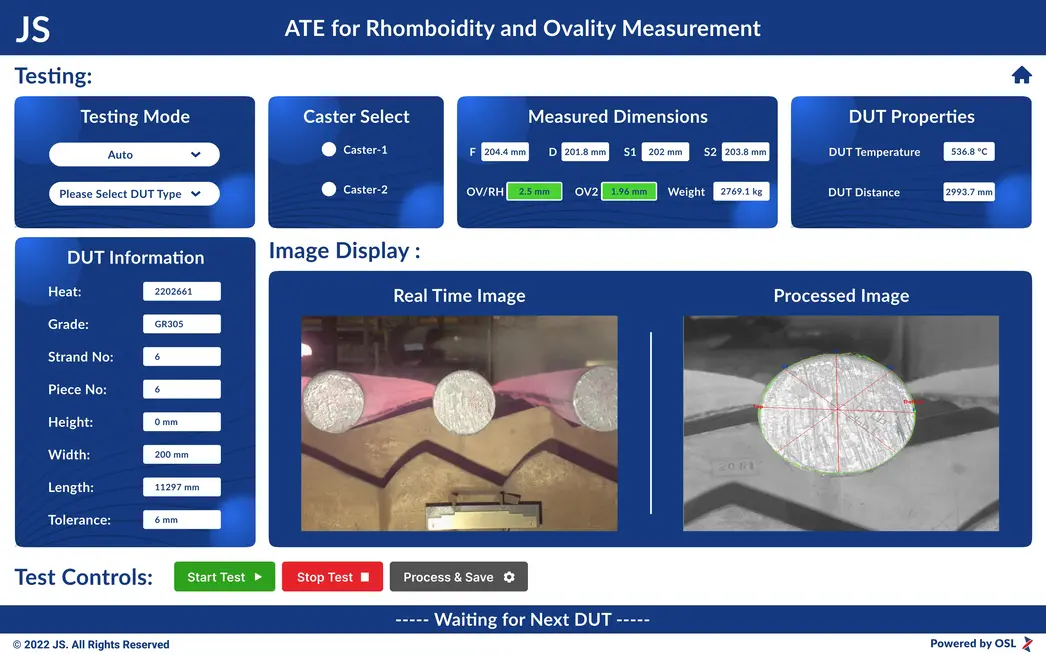

Real-time monitoring of production lines helps to ensure smooth operations, detect issues such as equipment malfunctions or quality defects promptly, and minimize downtime. Smart sensors and cameras can be used to monitor parameters like machine performance, product quality, and energy consumption.

Smart monitoring solutions can track the progress of products along the assembly line, monitor the performance of assembly machinery, and detect any deviations from the expected assembly process. This helps to maintain product quality and identify opportunities for process optimization.

Smart sensors and IoT devices can be deployed to monitor various parameters during manufacturing processes, such as temperature, pressure, humidity, and chemical composition. Real-time data analysis allows for proactive maintenance, process optimization, and quality control.

Comprehensive smart monitoring solutions can provide visibility into the entire manufacturing process, from raw material procurement to finished product delivery. This end-to-end monitoring helps identify inefficiencies, optimize resource utilization, and ensure compliance with quality standards and regulations.

Smart monitoring systems can track the performance and condition of manufacturing assets such as machinery, equipment, and vehicles. Predictive maintenance algorithms can analyze data from sensors to detect signs of equipment failure before it occurs, reducing downtime and maintenance costs.

Optimized Technologies is an end-to-end IoT solution provider, Starting from device user interface development and connectivity to data processing and cloud computing.

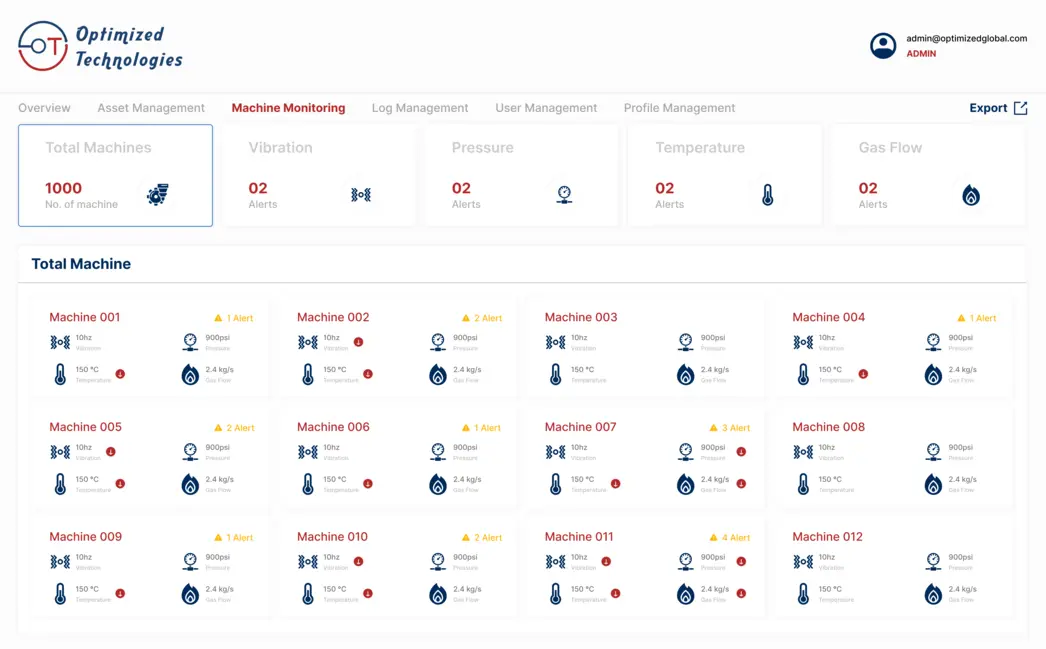

Monitoring a smart factory production line involves leveraging advanced technologies to enhance efficiency, quality, and overall productivity.

Preventive maintenance is a proactive approach to maintenance that leverages data, analytics, and machine learning to predict when equipment is likely to fail.

Smart asset monitoring and tracking involve utilizing advanced technologies to keep a close eye on assets, whether they are physical objects, equipment, vehicles, or even people, in real-time.

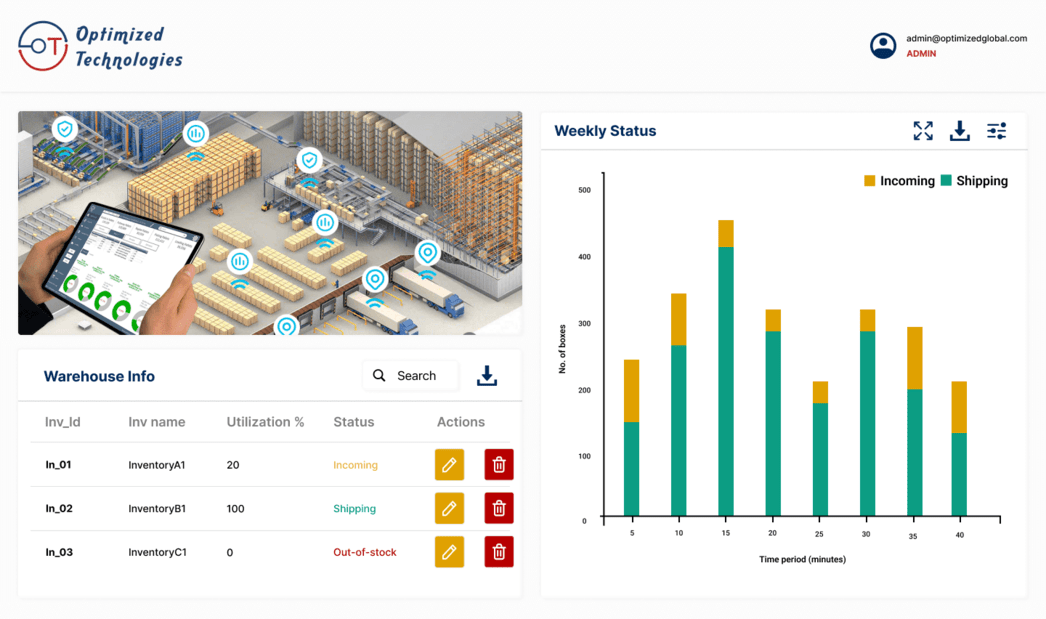

Smart inventory management is crucial for efficient and effective operations in various industries.

A vision-based condition monitoring solution utilizes cameras and image processing techniques to monitor the condition of equipment or processes.

Smart warehouses leverage advanced technologies to improve efficiency, accuracy, and overall operations in the storage and management of goods.

At Optimized Technologies, we advocate for Smart Manufacturing as it accelerates sales cycles by 25% to 50%, according to Salesforce. Embracing digital transformation is imperative to avoid market share loss and obsolescence. Our focus on Smart manufacturing, IoT, and software-driven processes enhances efficiency, quality, and competitiveness, ensuring future success.

At Optimized Technologies, we are actively leveraging the transformative potential of Industrial IoT for the manufacturing sector. Our applications embody six common themes, showcasing our dedication to innovation and efficiency in industrial processes.

Sensors, data, and big data analytics enable early equipment failure prevention. AI and machine learning enhance condition monitoring with minimal human intervention.

Industrial IoT, with real-time mobile dashboards, offers unprecedented visibility into production, enabling swift detection of inefficiencies, prompting adjustments, and improving equipment efficiency.

Automated building management systems integrate sensors, controllers, and equipment, enabling unified monitoring of energy usage. Broader datasets enhance informed perspectives on building performance.

In the industrial IoT era, supply chains become faster, flexible, and transparent. Manufacturers gain visibility into components, optimizing purchasing operations with real-time feedback.

Industrial IoT enables precise asset tracking, including hand-tools, in manufacturing plants. Connected tools 'learn' tasks, enhancing quality, and minimizing operator error risks.

Improve customer engagement and operational efficiency by adding smart components to products, collecting usage data, and utilizing real-world insights for refinements.

Benefit from our 19 years of IoT experience. Get complete IoT consulting services that are customized for your specific business needs.

Industry of

World

USA

IMTS –

International

Manufacturing

Technology

Show

AUTOMATE –

ROBOTS,

VISION,

MOTION,

SOLUTIONS

CES

Houstex

PLASTEC

West

Fabtech

National

Hardware

Show

BOILER

SEMICON

West

IoT Evolution

Expo

IoT Tech Expo

North

America

Optimized Technologies Inc. is a trusted IoT and Generative AI solutions provider, delivering secure, scalable, and end-to-end services for enterprises. Our deep expertise in device connectivity, data integration, and AI application design enables organizations to unlock actionable insights and automation. We build solutions with enterprise-grade security and cloud-ready scalability, ensuring performance and compliance at every stage. From consultation to deployment and continuous optimization, we provide complete lifecycle support tailored to business needs. With a proven track record across industries, we empower businesses to achieve digital transformation, enhance efficiency, and stay competitive in the era of AI and IoT.