Interface

Client Background

The client owns an Automobile manufacturing facility. The client’s customers include Tata and Toyota among others.

OTI Relationship with Client

This whole task requires continuous manual monitoring at the location which makes the whole process very tedious.

Challenges

The whole process of production data communication and fulfillment of the requirement of production is done by pen paper-based model and due to this manual process, it resulted in the information of slow data flow and an increase in dead stock, so a monetary loss is seen.

Therefore, this whole system needs to be modified to smoothen the whole process of manufacturing where OS provided a solution by developing a digitalized process of managing and controlling the production line & production inventory data to act accordingly.

Email, message, and notification:

- Notification to operator and engineer/manager after completion of upgradation of change over sheet with model number and quantity.

- Generate notifications if input/scanned data doesn’t match with the database values.

- Sheet assigning, sheet completion.

Responsive Web Application

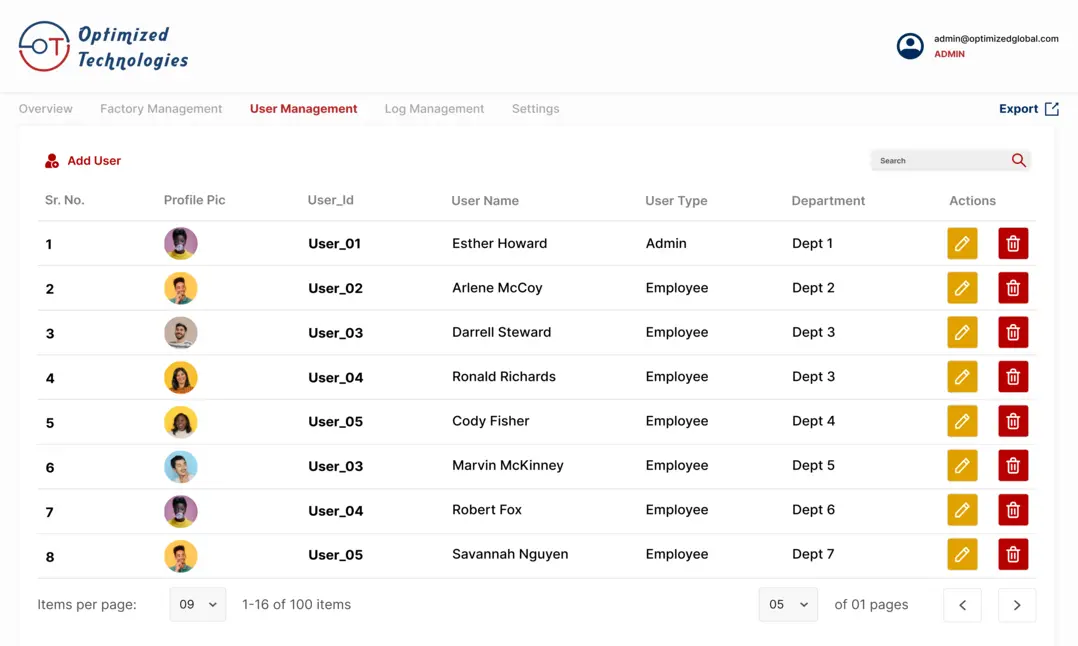

- Log in based software access to the user, based on hierarchy.

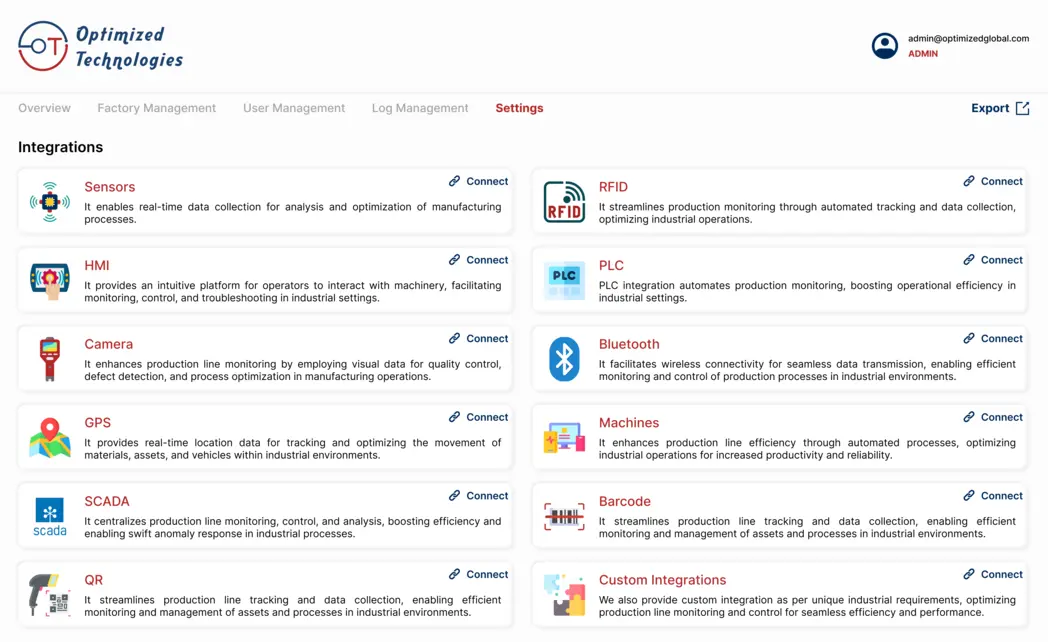

- Scanning of model/product using QR code while incoming of material or outgoing of material at production inventory for storage or usage.

- Inventory of production stock will be updated with respect to scanning of incoming models/products at production inventory

Solution

Digitization of production line and production inventory using real-time production line data and production inventory data visualization, real-time notification, tracking of the production process, and using a first in first out (FIFO) system for production process priority.

In/out scanning of model/product :

- QR code scanning for each individual product/model.

- Scanning of product/model while moving in/out from production inventory location.

- Product/model QR generation.

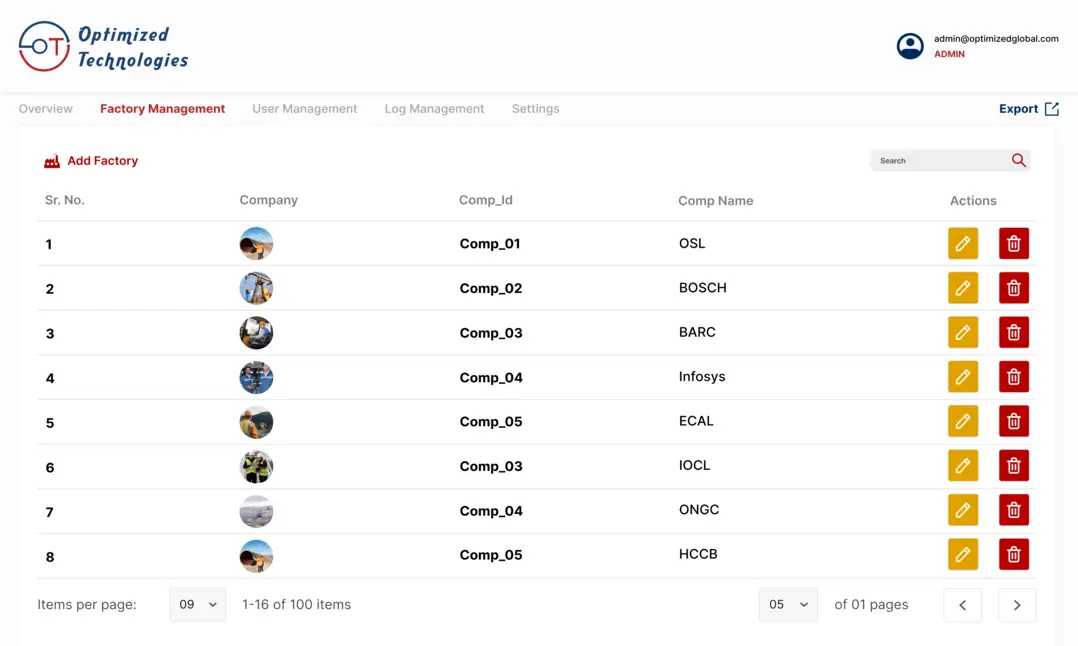

Centralized dashboard and database :

- Log-in credentials for different users.

- Hierarchy and department-wise reading and writing permission.

- If the actual existing production inventory stock of a specific product/model is less than the target value or threshold value at production storage stock, then a production request will open and will be sent to the production line for production of that specific model to fulfill the product/model requirement.

- Digital production orders placed will be shown as a pop-up at the production line in the production area to the specific user.

- Order placing for the specific model/product.

- Customizable lot size selection.

- Digital chute formation and reflection at the production line (priority-wise).

- Digital chute request will travel with the requested model/product from step one (start of manufacturing) till the final last step (completion of manufacturing).

- The request will travel through all the steps with the required model/product so that the specific user can track the process, also another user can work on the manufacturing process of the model/product.

- After the completion of the manufacturing of the requested product/model the manufacturing will be turned down and shown as completed and the final product/model will be then sent to the product inventory and the database of inventory will be updated accordingly.

- The model/product will be scanned and updated in the inventory database.

- The sequence of lot selection for production will be done using a first in first out (FIFO) system.

- Production process of each lot will be updated, and the data can be visualized.

- After completion of manufacturing of a specific lot, the request of that lot will be removed or deleted from the system.

- The products/models can be locked if required to stop sending the request of production of that specific product/model by mistake also. These models/products are not required and the production of the same is not required so there is a provision to lock that model/product so that the request for manufacturing does not move forward.

- The updating in the manufacturing can be done by inserting the set password and then after entering the password the process can be updated. Also, models and lot selection for manufacturing will be password protected.

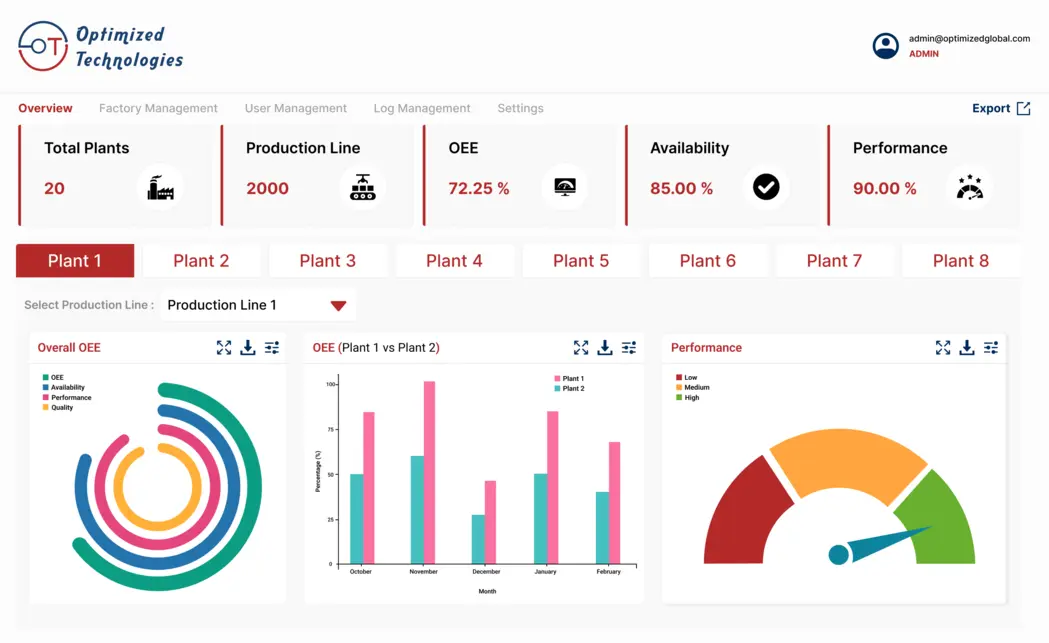

Smart Production Line Monitoring KPI

OEE

Measures equipment efficiency considering availability, performance, and quality.

Availability, Quality Measure

Assessment of equipment availability and output quality.

Performance Monitoring

Tracking metrics to evaluate production effectiveness.

Production Output & Target

Comparison of actual output to predetermined goals.

Breakdown time

Periods of equipment inactivity caused by failures, disrupting production continuity.

Shutdown Time

Planned halts in production for maintenance or upgrades.

Downtime

Periods when equipment or processes are inactive, impacting efficiency.

Throughput Rate

Speed of product production within a timeframe, affecting overall capacity.

Scrap Rate

Proportion of defective products generated during manufacturing.

Production Capacity

Maximum output achievable within a timeframe.

Mean Time Between Failure (MTBF)

Average time between equipment failures, indicating reliability.

Mean Time to Repair (MTTR)

Average time needed to repair equipment after a failure, influencing downtime.

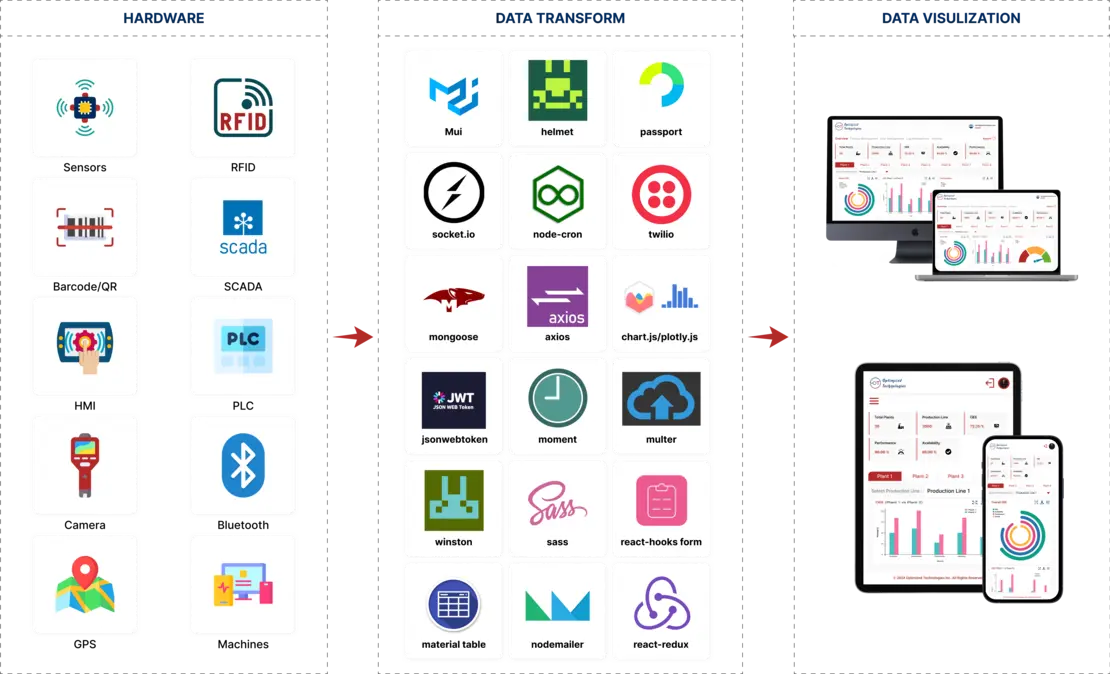

Data Flow

Case Study

Let us create an IoT strategy, implementation and evolve your IoT solution.

Technologies We Work With

Value Proposition

Optimized Technologies Inc. has provided a system for production line & production inventory with control & management.

By transforming the whole process digitally, the client will be able to reduce the number of dead stock as well as fasten the whole process of production eliminating the manual process.

Why Optimized Technologies Inc.?

Optimized Technologies Inc. is a trusted IoT and Generative AI solutions provider, delivering secure, scalable, and end-to-end services for enterprises. Our deep expertise in device connectivity, data integration, and AI application design enables organizations to unlock actionable insights and automation. We build solutions with enterprise-grade security and cloud-ready scalability, ensuring performance and compliance at every stage. From consultation to deployment and continuous optimization, we provide complete lifecycle support tailored to business needs. With a proven track record across industries, we empower businesses to achieve digital transformation, enhance efficiency, and stay competitive in the era of AI and IoT.