Interface

Client Background

The client owns an Automobile manufacturing facility. The client’s customers include Tata and Toyota among others.

OTI Relationship with Client

This whole task requires continuous manual monitoring at the location which makes the whole process very tedious.

Challenges

The machines and the spare parts need continuous monitoring and previously the software that client was using was not an effective one.

Therefore, this whole system needs to be modified to smoothen the whole process of manufacturing where analytics, centralized database, and alert system are developed into the software in order to get notified about the critical aspects in the facility.

Email, message, and notification:

- Notification to operator and engineer/manager after completion of upgradation of change over sheet with model number and quantity.

- Generate notifications if input/scanned data doesn’t match with the database values.

- Sheet assigning, sheet completion.

Solution

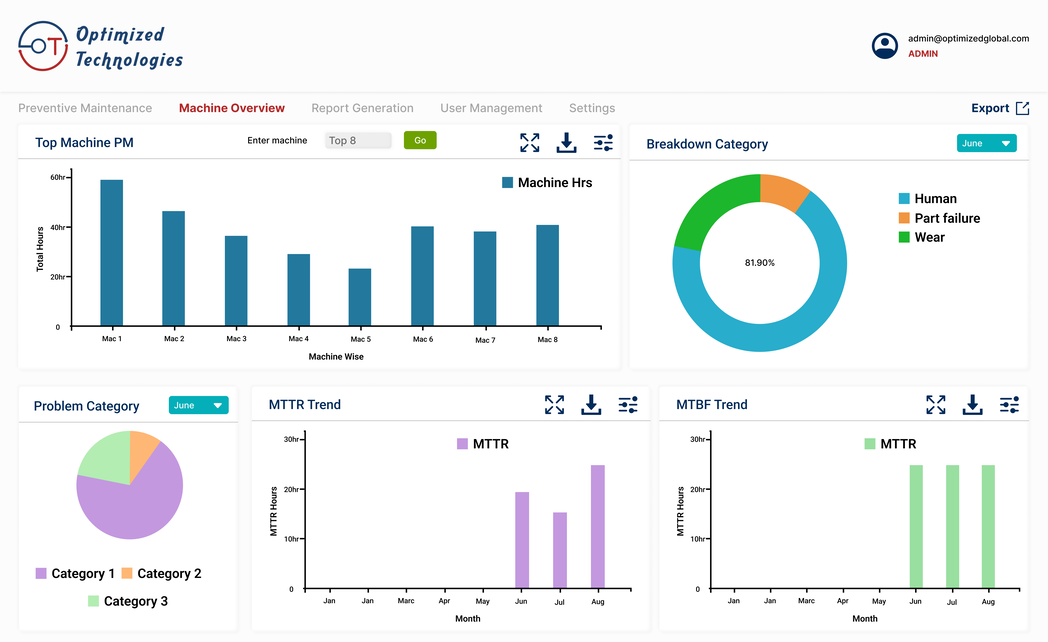

Centralized database and dashboard for data logging and data monitoring for a change-over sheet of machines

Centralized database and reports:

- Data history

- Log - In credentials for all users

- Machine spare parts reports

- History of spare parts usage and PM logs

- Trend reports

- PM and Spare (monthly, yearly) - section-wise, line-wise,

PM

update history.

PM time monitoring, abnormality status, section-wise TOP 20 spare

Responsive Web application

- Checklist for machine database on UI

- Digital signature of all users

- Comment section at the end of every checkbox

- New checkpoints generation in software application

- New machine addition to software application

- Machine spare part usage data (When, Where, and Why)

- Highly scalable.

- Multi-level user access.

Case Study

Let us create an IoT strategy, implementation and evolve your IoT solution.

Advance Data Analytics

- Report data - Line wise, Machine wise and Section wise

- Graphs, charts, sheet

- Data visualization

Hierarchy based operations, permissions, and features - (customizable):

- Add/edit/delete user

- Add/edit/delete check list points

- Add/edit/delete machines

- Different reading and writing permission of data based on hierarchy