Optimized technologies have successfully helped us take our technology & product to the next level by solving our remote visibility of misjudgement across lines, and steps with smart rule engine for notification and report download feature.We would highly recommend them in terms of expertise, professionalism & value driven quality of work. Kudos to Optimized Technologies for their work.

View More TestimonialsInterface

Client Background

The Council of Scientific and Industrial Research (CSIR) is a premier scientific research organization in India. Established in 1942, CSIR operates as an autonomous body under the Ministry of Science and Technology.

Challenges

The loading and transportation of the bulk materials are done via a conveyor belt.The movement of this conveyor belt is dependent on the motors attached to each belt.There is continuous manual monitoring required to handle the functioning of motors.

Therefore, this whole system needs to be digitally operated with minimum human intervention for the simplified functioning of the whole process through secure cloud management.Also, crucial protection must be provided to the whole system at the hardware edge.

Solution

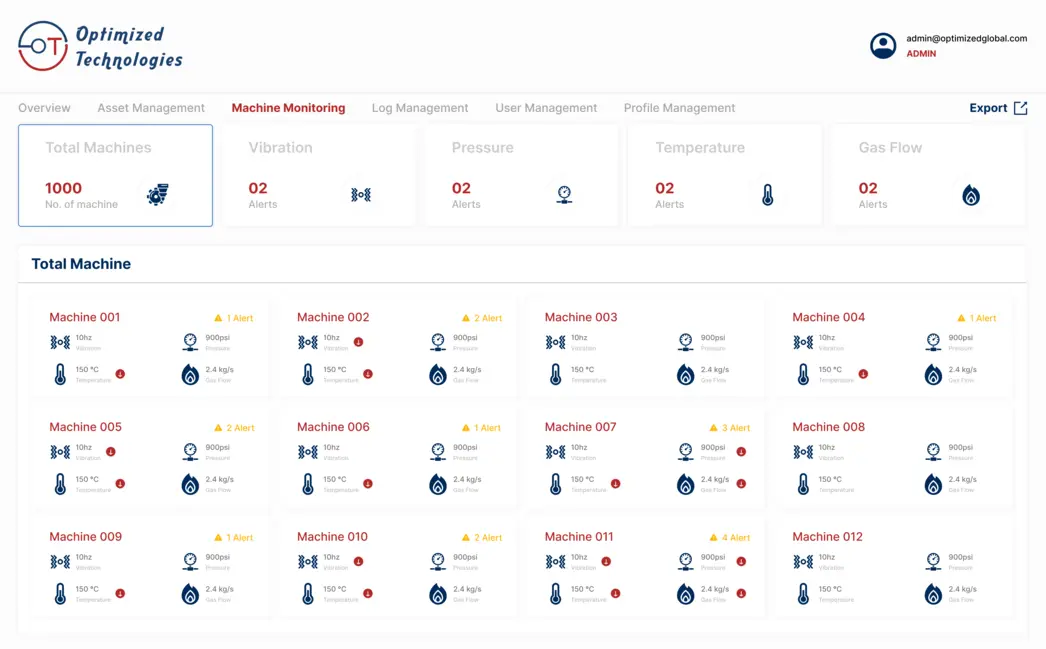

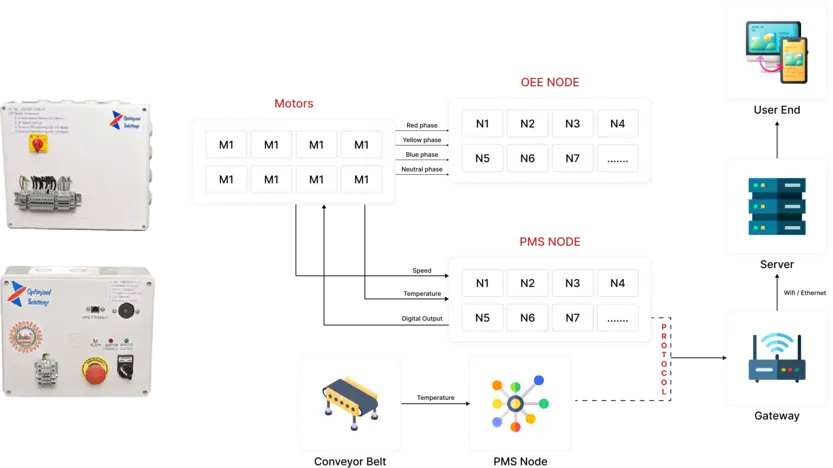

We have designed a flexible, and compatible system to monitor the whole loading and transportation system thereby incorporating the digital transformation by using various types of nodes and a unique gateway as a central hub which later sends the data to the cloud.

IoT NODES: To collect all physical quantities from operational technologies at coal plan, there are several types of IoT NODES deployed at the edge which convert the physical value into a digital value.IoT NODES have hardcore protection feature at edge for immediate action to avoid uncertain scenario.

OTI OEE Node

Key Features:

- 3-Phase current measurement

- 24-bit ADC resolution

- 5KHz Sampling frequency

- 0.2 Class measurement accuracy

- Easy to install with external CT for configurable current range

- Industry standard RS485 protocol

OTI PMS Node

Key Features:

- Configurable (Current/Voltage) Analog Input Channel

- Potential free contact (DO)

- 0.2 Class measurement accuracy

- Support 4-20mA or 0-10V

- EMI/EMC Certified: IEC-61000-4-4 (EFT), IEC-61000-4-3 (High Freq. field Immunity), IEC-61000-4-2 (ESD), IEC-61000-4-5 (Surge Immunity)

- Wireless communication: Secure 128-bit encryption

- Light weight & rugged

Applications:

The solution includes number of PMS NODES which can acquire different signal parameters such as current, temperature, speed of motor and temperature of conveyor belt. It also provides embedded digital output for immediate control action for example if a threshold limit crosses then it will automatically turn-off the motor/conveyer belt.

Gateway

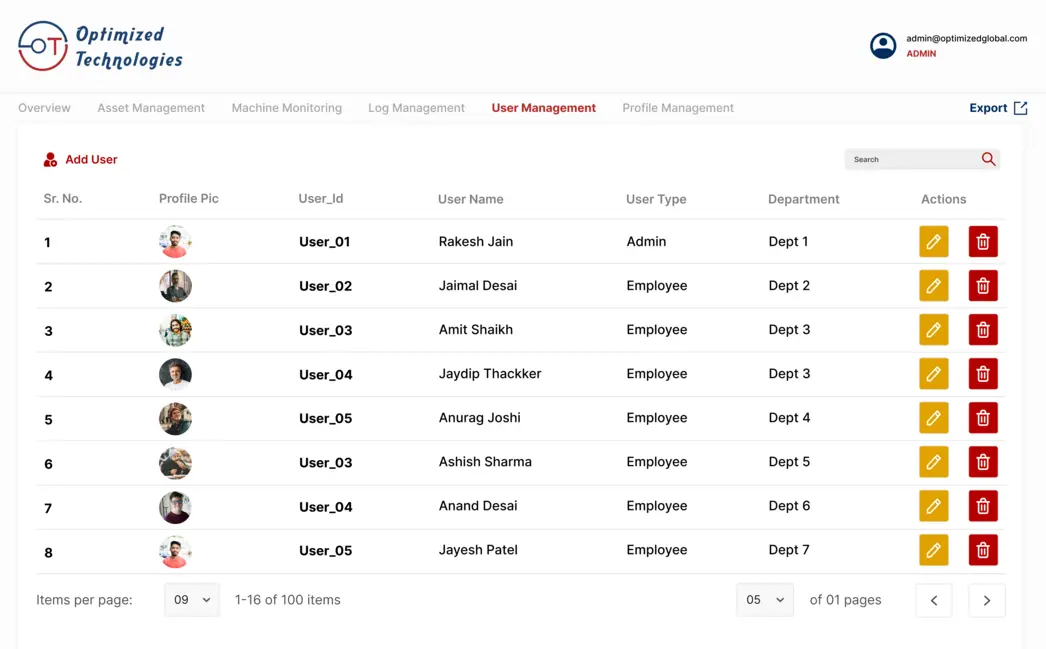

This gateway works as a centralized element to manage all IIoT NODES deployed on the field using secure wireless communication. It has inbuilt user-configurable algorithms to take critical decisions and actions via NODES. It works as a key element managing the local as well as remote networks using Ethernet/WiFi connectivity, hence providing user configuration features for add/remove the NODES in the local network.

Key Features:

Efficient Processor: 900 MHz, Quad core ARM Cortex A7 CPU, 1 GB RAM, 16 GB on-board storage memory and 64 GB external memory support, ARM GNU/Linux Operating System, Cloud connectivity using 802.11 b/g/n WiFi, 10/100 Base T Ethernet, Wireless Local connectivity using 2.4 GHz ZigBee, Easy to install and light weight

Applications:

Works as an intelligent intermediator between OT & IT. Manage all field NODES using a secure wireless local network, communication for data acquisition, and control action as per configuration. It takes the dataset to the Cloud/Server for further analysis and presentation. We have integrated the feature for Manual/Automated operation depends on the situation. also, we have delivered some customization for the embedded physical emergency push button as per customer requirements.

Architecture

Case Study

Let us create an IoT strategy, implementation and evolve your IoT solution.

Benefits

- User friendly / Simplified

- Compatible

- Customized

- Continuous monitoring

- Results driven data analytics

- Automated/Manual driven process

- Crucial data protection

Benefits against alternatives

- A system that is compatible with the existing process for simultaneous controlling and monitoring of loading and transportation in the coal mining process.

- The specific node and gateway used in the solution make the process more simplified by controlling and monitoring the conveyor belts and motors parameters.

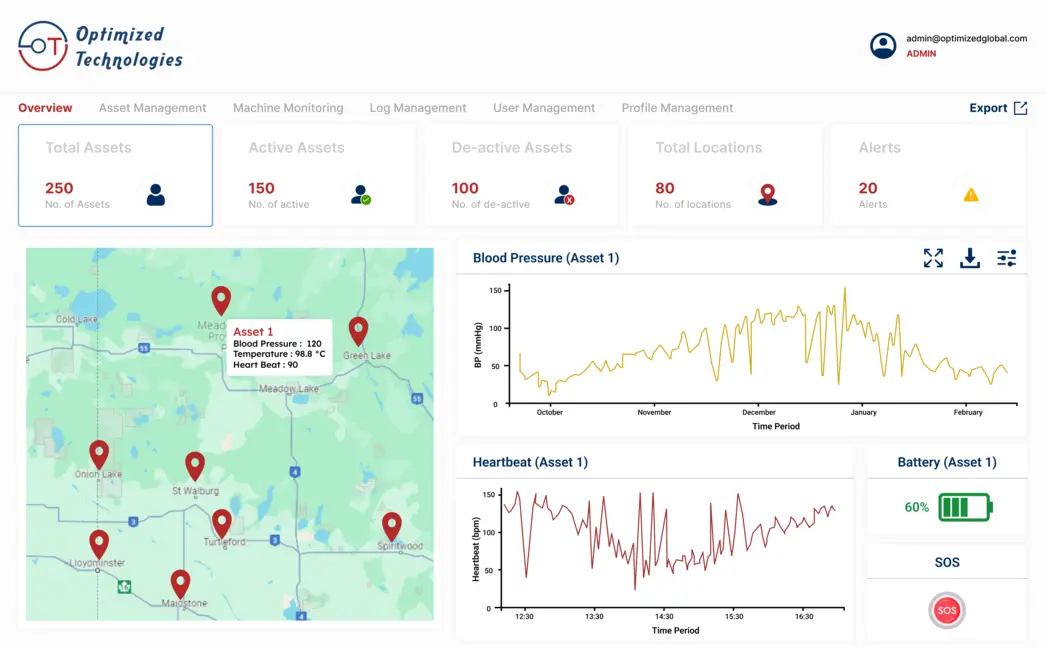

- Through the application on the user end the user can monitor the specific parameters thereby getting to analyze the whole process graphically.

- Time-to-time notifications and alerts will be prompted if there is any kind of error occurring in the process, hence easing the whole loading and transportation process by digitally controlling and monitoring it.